There are many grades and types of controlled environment wipes in the market, each with inherently different attributes, and levels of releasable fiber. Post processing can impact these performance attributes, and new fiber technologies provide new choices to users.

There are many grades and types of controlled environment wipes in the market, each with inherently different attributes, and levels of releasable fiber. Post processing can impact these performance attributes, and new fiber technologies provide new choices to users.

As a reference, “lint-free” implies there is no visible lint on the wiper surface with the inspection of the un-aided eye. However, upon closer inspection, every fabric has some level of lint. Upon magnification, vast differences will be realized between fabric types and grades.

Typically, non-woven wipes are produced by hydro-entangling millions of short fibers together to create the substrate. This creates a strong bond, however under force, the short fibers will break and be released as “lint” onto the applied surface. This is particularly true with wipers containing cellulose; as they are used wet the cellulose has a high probability of being left behind on your surface when enough force is applied. These short fiber non-woven wipes are properly considered as “low-linting” and should be used for general applications with low risk where this is suitable.

Historically, a “non-linting” wiper is comprised of continuous thread of synthetic yarn (like polyester, nylon, or polyester/nylon microfiber) which is knit or woven to provide excellent mechanical strength. Edges must be sealed (ultrasonic or laser) when cut to prevent fiber release while in use. After construction of the “grey” material, post-process cleanroom washing with ultra-pure water removes any releasable contaminant and fiber from the wiper surface; which provides the levels of lint and cleanest intrinsic purity. These synthetic laundered wipers have been the staple choice for “lint-free” cleaning of critical surfaces. Natural materials cannot be considered (cellulose, cotton) as they inherently continue to release fiber. The disadvantage to these synthetic materials is the hydrophilic nature, which repels water and limits liquid sorption.

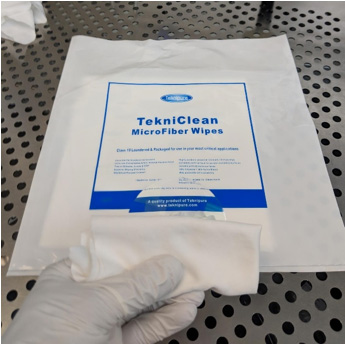

Today, Teknipure has introduced a new family of “lint-free” non-woven microfiber wipes for all applications demanding intrinsic cleanliness and extrinsic performance. These Teknizorb wipes are comprised of long fibers and produced with a superior process which provides for a bond similar to knit or woven construction. We wash this non-woven fabric with ultra-pure water, which provides an exceptionally soft and absorbent material suitable for any controlled environment; providing a new option for many applications in need. Teknipure manufactures non-woven microfiber intended for use in all ISO classifications, in addition to woven & knit microfiber.

Use of a “low-linting” (lower cost) wiper in a critical application will most likely cause catastrophic results. Your wiper is intended to protect your valuable products. However, specification review and proper selection significantly impact the result of use.

For more information about these Teknipure products, contact your Thomas Scientific representative.