ABOUT MICROVENTION

MicroVention is a medium-sized neuroendovascular medical device company that develops minimally-invasive devices for treatment of vascular diseases in the brain. They have three locations. Their parent company has an additional fourteen locations and is a global top twenty medical device company.

PROBLEM

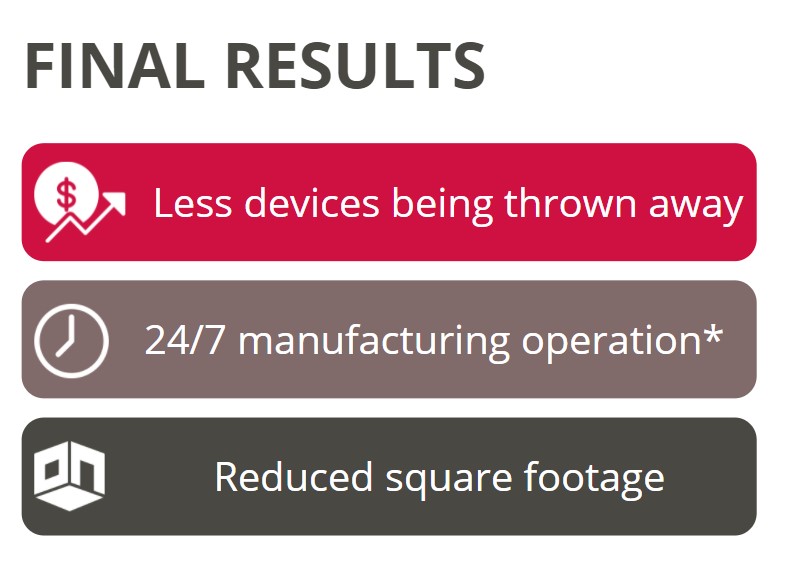

MicroVention was writing multiple purchase orders per week, as they were scaling up they started to encounter problems with the amount of PO's they were writing. Particle problems within their cleanrooms were causing devices to be reworked or latent failures. Sometimes throwing devices away due to these particle problems. Storage was also a large issue.Additionally, they are located in California where there is little space for their growing warehouse needs.

WHY A THOMAS INVENTORY MANAGEMENT SOLUTION?

Thomas was able to go into MicroVention to consult on new solutions with their particle problems, offer better products, and switch out those products. Thomas made eliminating the stress of multiple purchase orders a top priority. Through a TIMS, we were also able to open up storage options for MicroVention. Thomas's just-in-time stocking solution helped alleviated the high cost of storage.

.png)

SYSTEM IMPLEMENTATION

Two of their locations have implemented TIMS, a level 1 location, and a level 2 location. The third location is a buy-sell relationship and quoting for other products. The Thomas team is counting and filling multiple orders at the same time, eliminating the need for multiple purchase orders. They come up with a weekly order and it is on a truck within 48 hours. Thomas counts the order and ensures everything is accounted for.

During the COVID-19 pandemic, MicroVention never ran out of products, within minutes Thomas was making recommendations for alternative products for the time being resulting in 0 downtimes. Thomas was able to reduce their storage from 100 square feet to 10 square feet. MicroVention was able to utilize the storage space for more manufacturing space.

LOOKING FORWARD

Thomas is looking to turning our buy-sell relationship with their third location into a VMI serviced location, as well as moving one of their locations from a lower level 2 to a full level 2. Thomas is looking into being added to MircroVention's punch-out system, further eliminating the stress of multiple purchase orders. Adding additional products to their product catalog is also a large priority for Thomas.

Serving the scientific community for over 120 years, we put our customers first!

Thomas Scientific has partnered with hundreds of customers to provide best-in-class vendor managed inventory programs with you in mind. We have a proven track record to manage customer inventory freeing you up to manage your business.

.png)